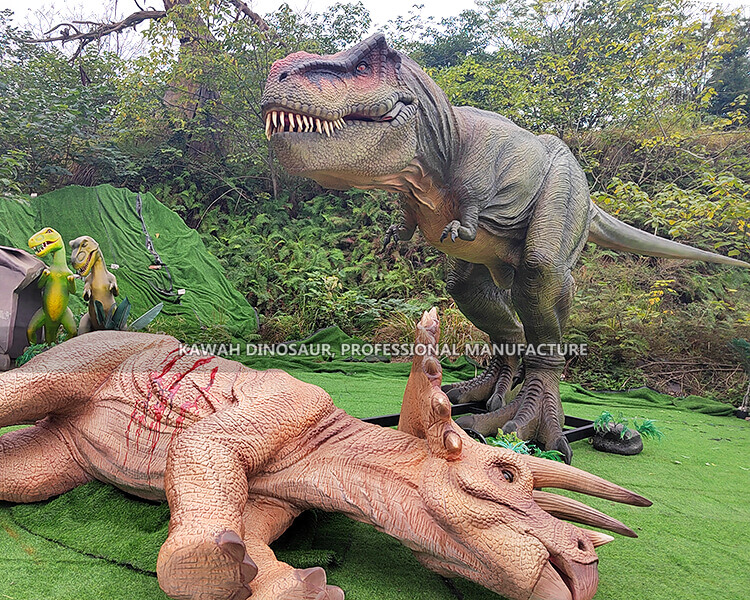

Realistic Dinosaur Models Dinosaur Animatronic T-Rex Fighting AD-024

Product Video

Animatronic Dinosaurs Parameters

| Size: From 1m to 30 m long, other size is also available. | Net Weight: Determined by the size of the dinosaur (eg: 1 set 10m long T-rex weighs close to 550kg). |

| Color: Any color is available. | Accessories: Control cox, Speaker, Fiberglass rock, Infrared sensor, etc. |

| Lead Time:15-30 days or depends on quantity after payment. | Power: 110/220V, 50/60hz or customized without extra charge. |

| Min. Order Quantity: 1 Set. | After Service: 24 Months after installation. |

| Control Mode: Infrared sensor, Remote control, Token coin operated, Button, Touch sensing, Automatic, Customized, etc. | |

| Usage: Dino park, Dinosaur world, Dinosaur exhibition, Amusement park, Theme park, Museum, Playground, City plaza, Shopping mall, Indoor/outdoor venues. | |

| Main Materials: High-density foam, National standard steel frame, Silicon rubber, Motors. | |

| Shipping: We accept land, air, sea transport, and international multimodal transport. Land+sea(cost-effective) Air(transport timeliness and stability). | |

| Movements: 1. Eyes blinking. 2. Mouth open and close. 3. Head moving. 4. Arms moving. 5. Stomach breathing. 6. Tail swaying. 7. Tongue Move. 8. Voice. 9. Water spray.10. Smoke spray. | |

| Notice: Slight differences between the objects and the pictures because of handmade products. | |

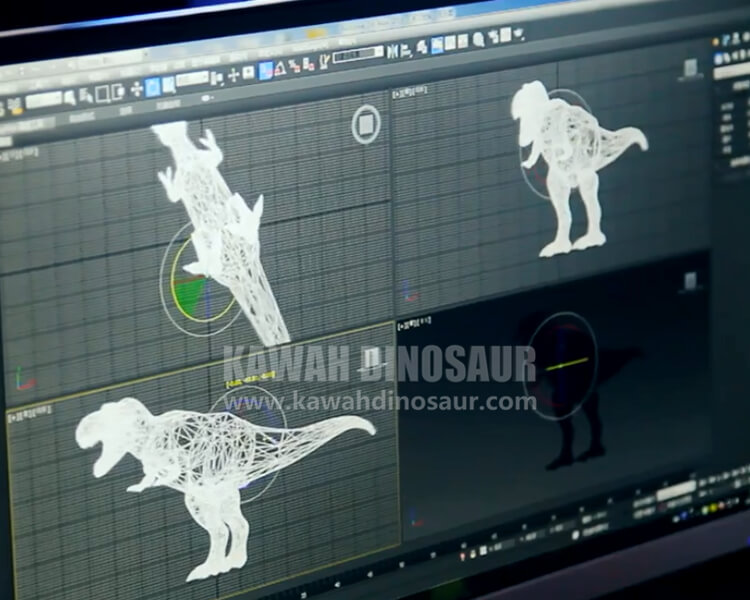

Dinosaur Manufacturing Process

1. Drawing Design

* According to the species of the dinosaur, the proportion of limbs, and the number of movements, and combined with the needs of the customer, the production drawings of the dinosaur model are designed and produced.

2. Mechanical Framing

* Make the dinosaur steel frame according to the drawings and install the motors. Over 24 hours of steel frame aging inspection, including motions debugging, welding points firmness inspection and motors circuit inspection.

3. Body Modeling

* Use high-density sponges of different materials to create the outline of the dinosaur. Hard foam sponge is used for detail engraving, soft foam sponge is used for motion point, and fireproof sponge is used for indoor use.

4. Carving Texture

* Based on references and the characteristics of modern animals, the texture details of the skin are hand-carved, including facial expressions, muscle morphology and blood vessel tension, to truly restore the dinosaur's form.

5. Painting & Coloring

* Use three layers of neutral silicone gel to protect the bottom layer of the skin, including core silk and sponge, to enhance the skin's flexibility and anti-aging ability. Use national standard pigments for coloring, regular colors, bright colors, and camouflage colors are available.

6. Factory Testing

* The finished products undergo an aging test for more than 48 hours, and the aging speed is accelerated by 30%. Overload operation increases the failure rate, achieving the purpose of inspection and debugging, and ensuring product quality.

Why choose Kawah Dinosaur

* FACTORY SALES AT COMPETITIVE PRICES.

- Self-owned dinosaur factory, no intermediaries are involved, most competitive price to save you costs. Kawah dinosaur could provide you with design, manufacturing, installation, and after-sale services one-stop shopping experience.

* HIGHLY SIMULATED CUSTOM MODEL.

- Kawah Dinosaur Factory can customize any animatronic model, you just need to provide pictures and videos. Our advantages are simulation model detail processing, skin texture processing, stable control system, and strict quality inspection.

* 500+ CLIENTS WORLDWIDE.

- We have designed 100+ dinosaur exhibitions, theme dino parks, and other projects, with 500+ customers worldwide, which are very popular with local tourists. Won the trust of many customers and established long-term business relations with them.

* EXCELLENT AFTER-SALE SERVICE.

- We will track your products throughout entire process and provide you with the processing feedback. We will send a professional team to assist with the installation as you need and repair the product in a quality guarantee period at any time.

Certificates And Capability

As the product is the base of an enterprise, Kawah dinosaur always puts product quality first place. We strictly select the materials and control every production process and 19 testing procedures. All products will be made for aging test over 24 hours after the dinosaur frame and finished products are finished. The products' video and pictures will be sent to customers after we finish the three steps: dinosaur frame, Artistic shaping, and finished products. And products are only sent to customers when we get the customer's confirmation at least three times.

Raw materials & products all reach related industry standards and acquire related Certificates(CE,TUV.SGS.ISO)