Jurassic Park Animatronic Dinosaur Life Size Dinosaur Ichthyosauria AD-159

Product Video

What's Animatronic Dinosaur?

Animatronic Dinosaur is the use of cable-pulled devices or motors to emulate a dinosaur or bring lifelike characteristics to an otherwise inanimate object.

Motion actuators are often used to imitate muscle movements and create realistic motions in limbs with imaginary dinosaur sounds.

Dinosaurs are covered with body shells and flexible skins made of hard and soft foam and silicone materials and finished with details like colors, hair, feathers, and other components to make the dinosaur more lifelike.

We consult with paleontologists to make sure that each dinosaur is scientifically realistic.

Our life-like dinosaurs are loved by visitors to Jurassic Dinosaur Theme Parks, museums, scenic spots, exhibitions, and most dinosaur lovers.

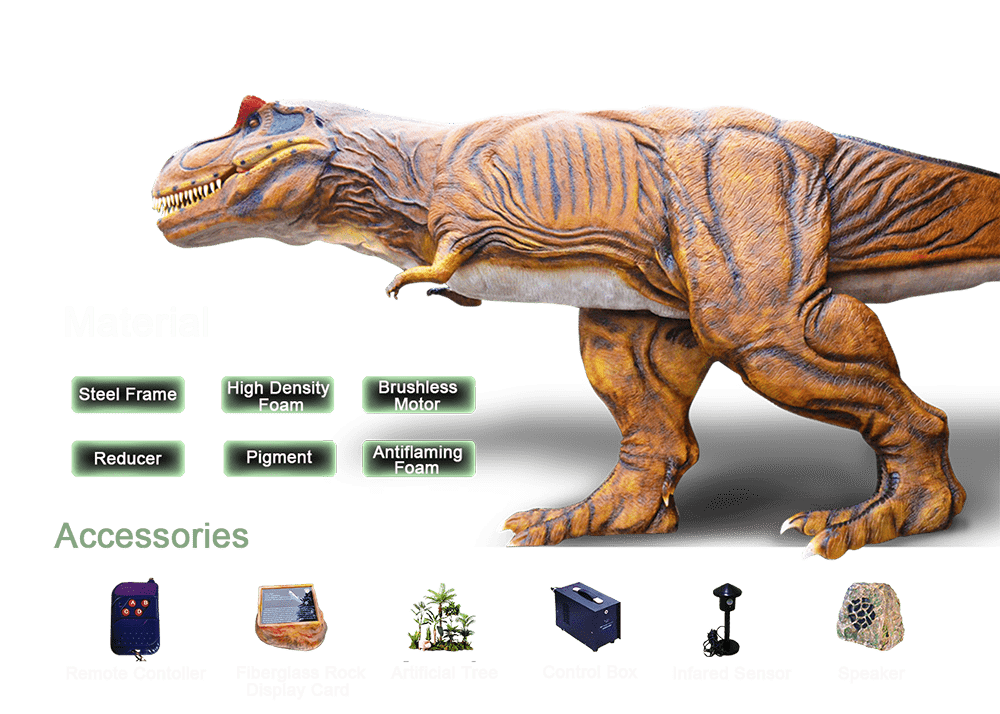

Animatronic Dinosaurs Main Materials

Co-Brands

Over the past 12 years of development, the products and customers of the Kawah Dinosaur factory have been spread all over the world. We not only have a complete production line, but also have independent export rights, to provide you with design, production, international transportation, installation, and a series of services. Our products have been sold to more than 30 countries such as the United States, Britain, France, Russia, Germany, Romania, United Arab Emirates, Japan, South Korea, Malaysia, Chile, Peru, Ecuador, South Africa, and so on. The simulated dinosaur exhibition, Jurassic park, dinosaur theme park, insect exhibition, marine life exhibition, amusement park, theme restaurants, and other projects are very popular with local visitors, and we have gained the trust of many customers and established long-term business relations with them.

Dinosaur Manufacturing Process

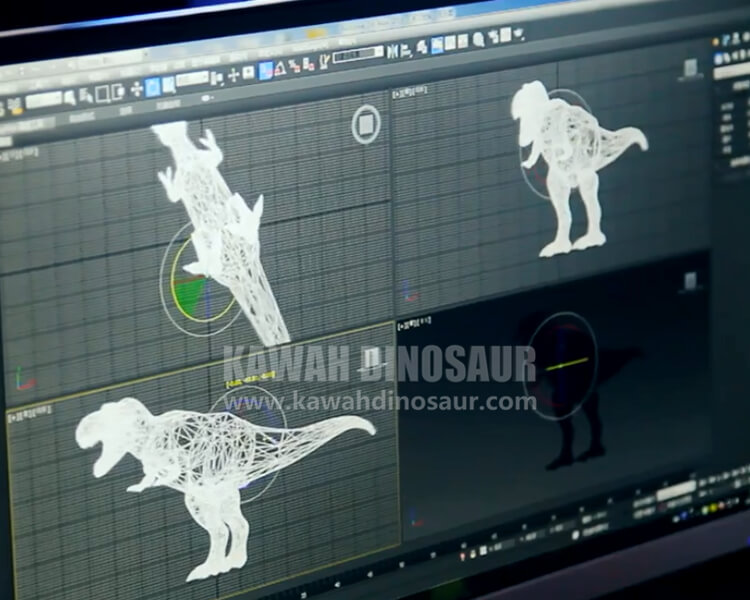

1. Drawing Design

* According to the species of the dinosaur, the proportion of limbs, and the number of movements, and combined with the needs of the customer, the production drawings of the dinosaur model are designed and produced.

2. Mechanical Framing

* Make the dinosaur steel frame according to the drawings and install the motors. Over 24 hours of steel frame aging inspection, including motions debugging, welding points firmness inspection and motors circuit inspection.

3. Body Modeling

* Use high-density sponges of different materials to create the outline of the dinosaur. Hard foam sponge is used for detail engraving, soft foam sponge is used for motion point, and fireproof sponge is used for indoor use.

4. Carving Texture

* Based on references and the characteristics of modern animals, the texture details of the skin are hand-carved, including facial expressions, muscle morphology and blood vessel tension, to truly restore the dinosaur's form.

5. Painting & Coloring

* Use three layers of neutral silicone gel to protect the bottom layer of the skin, including core silk and sponge, to enhance the skin's flexibility and anti-aging ability. Use national standard pigments for coloring, regular colors, bright colors, and camouflage colors are available.

6. Factory Testing

* The finished products undergo an aging test for more than 48 hours, and the aging speed is accelerated by 30%. Overload operation increases the failure rate, achieving the purpose of inspection and debugging, and ensuring product quality.