Customized Artificial Gold Color T-Rex Dinosaur Skeleton Replicas for Dino Park Show PA-1998

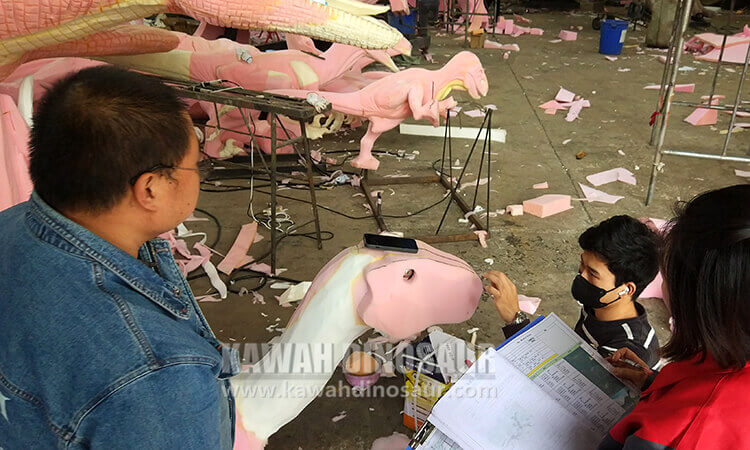

Product Quality Inspection

We attach great importance to the quality and reliability of our products, and we have always adhered to strict quality inspection standards and processes throughout the production process.

Check Welding Point

* Check whether each welding point of the steel frame structure is firm to ensure the stability and safety of the product.

Check Movement Range

* Check whether the movement range of the model reaches the specified range to improve the functionality and user experience of the product.

Check Motor Running

* Check whether the motor, reducer, and other transmission structures are running smoothly to ensure the performance and service life of the product.

Check Modeling Detail

* Check whether the details of the shape meet the standards, including appearance similarity, glue level flatness, color saturation, etc.

Check Product Size

* Check whether the product size meets the requirements, which is also one of the key indicators of quality inspection.

Check Aging Test

* The aging test of a product before leaving the factory is an important step in ensuring product reliability and stability.

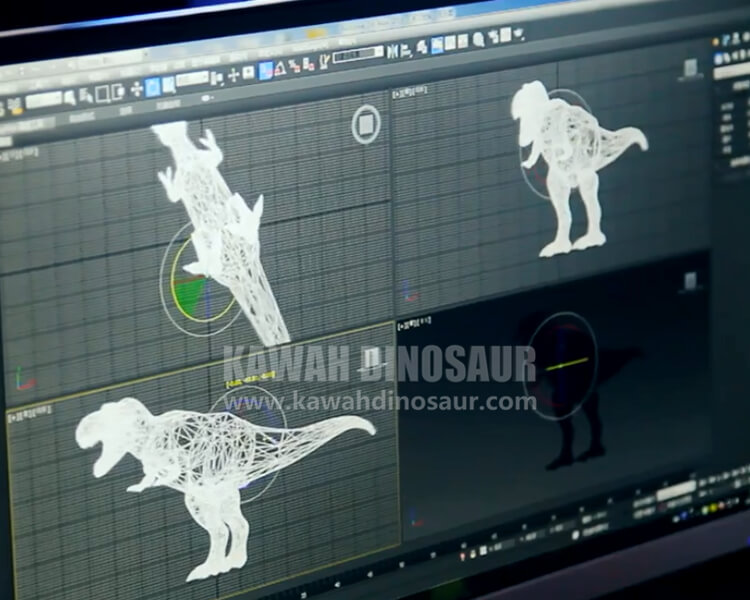

Dinosaur Manufacturing Process

1. Drawing Design

* According to the species of the dinosaur, the proportion of limbs, and the number of movements, and combined with the needs of the customer, the production drawings of the dinosaur model are designed and produced.

2. Mechanical Framing

* Make the dinosaur steel frame according to the drawings and install the motors. Over 24 hours of steel frame aging inspection, including motions debugging, welding points firmness inspection and motors circuit inspection.

3. Body Modeling

* Use high-density sponges of different materials to create the outline of the dinosaur. Hard foam sponge is used for detail engraving, soft foam sponge is used for motion point, and fireproof sponge is used for indoor use.

4. Carving Texture

* Based on references and the characteristics of modern animals, the texture details of the skin are hand-carved, including facial expressions, muscle morphology and blood vessel tension, to truly restore the dinosaur's form.

5. Painting & Coloring

* Use three layers of neutral silicone gel to protect the bottom layer of the skin, including core silk and sponge, to enhance the skin's flexibility and anti-aging ability. Use national standard pigments for coloring, regular colors, bright colors, and camouflage colors are available.

6. Factory Testing

* The finished products undergo an aging test for more than 48 hours, and the aging speed is accelerated by 30%. Overload operation increases the failure rate, achieving the purpose of inspection and debugging, and ensuring product quality.